Straight panelfences 2D

We offer comprehensive fencing systems, which we make from profiled or straight welded panels. All are equipped with fixing posts and mounting accessories.

We manufacture customised gates and wickets to customers' specifications. We offer both swing and sliding solutions.

Application: Panel fences have a wide range of applications. Particularly recommended for securing: factories, warehouses, stadiums, sports facilities, schools, public buildings, private properties.

Technical specifications

| height of fence [mm] |

height of post [mm] |

number of fixings per intermediate, end and corner post | mesh size [mm] |

wire diameter ø[mm] |

|---|---|---|---|---|

| 1030 | 1600 | 2 | 50×200 | 6×5×6 or 8×6×8 |

| 1230 | 1800 | 2 | ||

| 1430 | 2000 | 3 | ||

| 1630 | 2400 | 3 | ||

| 1830 | 2400 | 3 | ||

| 2030 | 2600 | 4 |

Implementation

We produce panel fences from galvanised steel wires, which can additionally be powder-coated. The same applies to the posts - the decision on the use of colour is made by each individual customer.

In addition to high durability, the fences and posts are also characterised by resistance to corrosion. The latter are provided with PVC top caps, which protect the interior from water ingress.

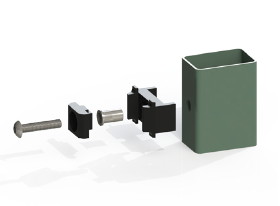

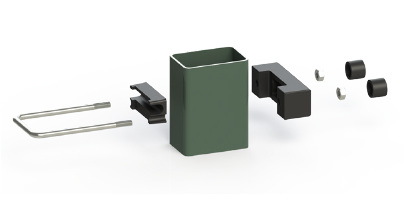

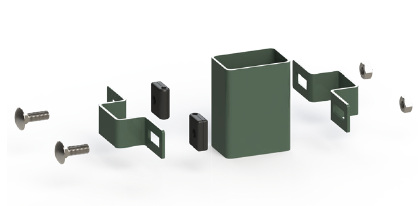

Mounting

Attaching the panels to the uprights is very simple and is done by means of fixing brackets, which also make it possible to adjust the settings.

-

Hook bolt

-

Plastic base

-

Cybant

-

Clamp

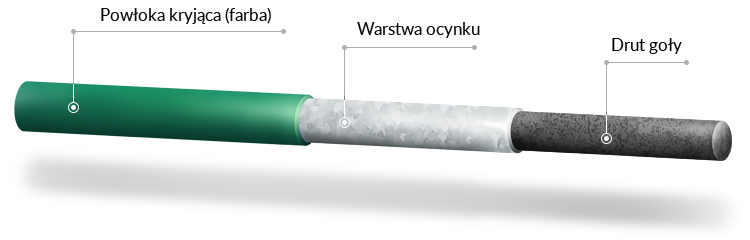

Galvanising and powder coating

Corrosion protection for up to 15 years

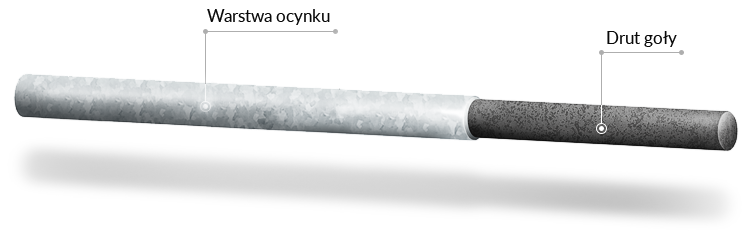

Hot dip galvanizing

The fencing elements undergo a careful and multi-stage cleaning process followed by the formation of a protective, anti-corrosion coating with molten zinc.

Hot-dip galvanising consists in immersing a suitably prepared element in molten zinc at a temperature of 450-460°C, where a very strong inter-particle bonding of Fe-Zn is formed, protecting against corrosion for up to 50 years. The advantage of this method is that the zinc coating is applied evenly even in hard-to-reach areas (bends, grooves). The average thickness of the protective coating obtained is between 50 and 70 µm.

Increased resistance to corrosion, chemicals, temperature, chemical damage

Galvanising + powder coating

The individual elements of the fence, previously galvanised, undergo a powder coating process in an individually selected colour from the standard RAL palette.

The painting process is based on the application of powder paint by electrostatic spraying. Charged paint particles are deposited on the surface to be painted and then subjected to a curing process in an oven at a temperature of 200°C, creating a lacquer coating resistant to corrosion, chemicals, heat and mechanical damage.